I. Industry

Industrial intelligent machines are widely used in manufacturing process in factories. The scene is a repetitive and continuous action. During the process, the produced products need to be lifted and moved for a certain distance or angle before being put down and it must be ensured the products wont’ fall during the process of moving or rotating and will be put down continuously when it reaches the set position. Such a simple and repetitive action is more convenient to complete with an intelligent machine. In addition to robotic arms, electromagnets and conveyor belts, the use of vacuum suction principles to transport and transfer smooth objects is also widely used in production automation. For example, in the process of producing the photo frame, the photo frame factory will use the intelligent machine to repeat the cycle of moving the photo frame. In addition to making assembly line production faster, it can also free up more labor and reduce costs.

II.Application of micro vacuum pump

Theoretically, the adsorption force can be calculated. Methods as below:

F≈10-2 (101-P absolute pressure) S suction cup area

In the above formula,

F: Theoretical adsorption force, unit: Kgf (kg force)

P Absolute pressure: the absolute vacuum degree of the micro vacuum pump, the unit is kPa (kPa)

S suction cup area: the effective area of the suction cup, the unit is cm2 (square centimeter)

It can be seen from the above formula that the size of the adsorption force theoretically has nothing to do with the flow rate of the pump, but in actual use it is related to the flow parameter. The reason is as follows: because the air circuit system cannot achieve theoretical sealing, there is always a certain amount of leakage. In this case, the larger the flow rate of the micro vacuum pump, the smaller the proportion of leakage, which is more conducive to the pump maintaining a higher vacuum degree, thereby obtaining a greater adsorption force. For example, if there are two pumps with the same ultimate vacuum degree, the flow rate of pump A is 1 L/min, and the flow rate of pump B is 20 L/min. In the case of a leakage of 0.1 L/min, the vacuum degree of pump A will decrease a lot. Because the leakage of 0.1 L/min is too large for it. However, the leakage of 0.1 L/min is nothing to pump B, and it can still maintain a high vacuum. Therefore, although the vacuum degree of the two is the same, in practice, the adsorption force produced by the B pump is greater. Therefore, both the vacuum degree and flow rate must be considered simultaneously when selecting the pump type. It is impractical to only focus on the vacuum degree.

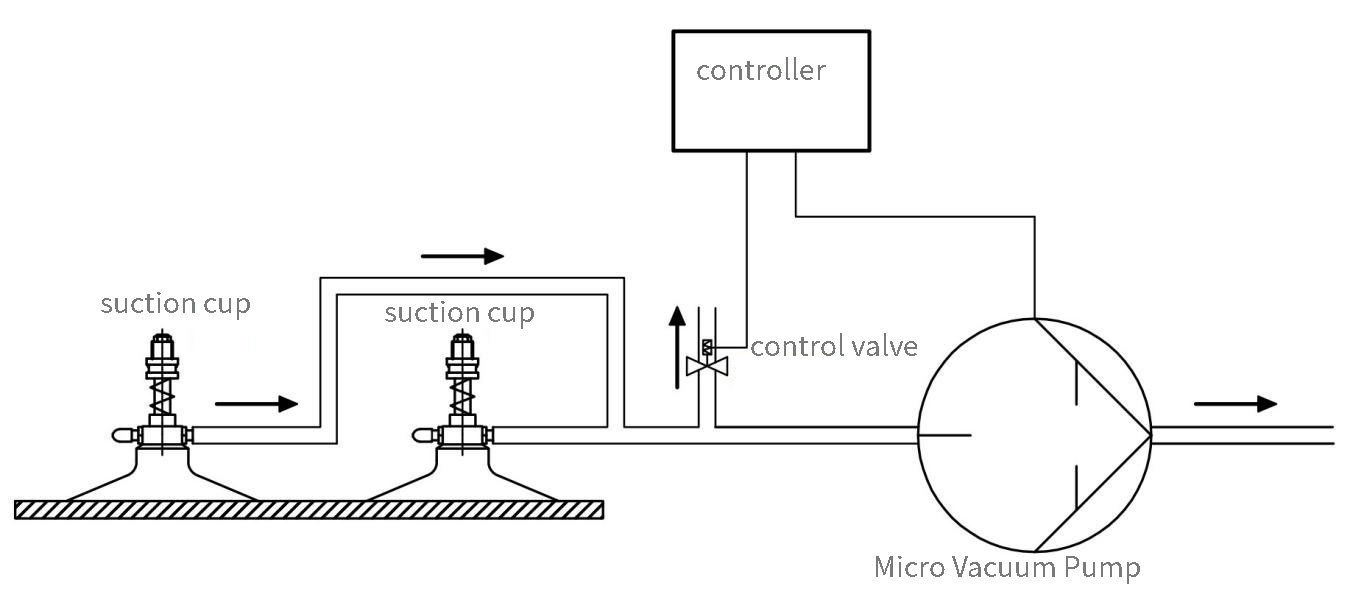

2. Gas circuit connection

Adopting multiple suction cups to adsorb the production products can become more stable and reliable. Generally, the gas circuit connection between the suction cup and the suction cup can be connected in series and in parallel. However, the use of a parallel air circuit and a vacuum check valve can ensure that even if one of the suction cups leaks, another suction cup can also firmly adsorb the product, and the product will not fall easily when the machine picks up and moves the products.

3. Release the object

When it is necessary to release the sucked object, the pump must be stopped first to discontinue the vacuum. After the pump is stopped, the object may not fall off immediately, because the pump has a certain pressure holding capacity, and can maintain the vacuum for a while. To release the object immediately, the gas system should add another branch, connect an on-off valve, stop the pump and open the valve at the same time, and immediately eliminate the vacuum in the gas system so that the object can be reliably released.

III. Project Difficulties

1. The on-site space is limited, there is no air compressor, and the vacuum generator cannot be used. The vacuum environment can only be created by the vacuum pump.

2. When working continuously,the pump needs to start and stop frequently and can be controlled remotely to facilitate integration with PLC and other controllers.

3. With relatively small volume,high vacuum and large flow can ensure fast adsorption and large adsorption capacity.

IV. Solution

2. The C series miniature vacuum pump developed and produced by Chengdu Hilin Technology is powered by a DC24V DC power supply with low power consumption; according to different site conditions, it can be powered by direct plug-in power supply or external storage battery. It can be randomly moved for use on site.

3. The C series mini vacuum pump developed and produced by Chengdu Hilin Technology, in order to meet the more comprehensive needs on the site, specially added a remote soft-start control port to some vacuum pump panel terminals, which can be combined with the field circuit control unit to achieve remote control,start and stop of the vacuum pump frequently.

In the end, the customer chose Hilin Technology's C60 micro vacuum pump as the vacuum source to drive the vacuum cup on the assembly line to achieve large flow, high vacuum and continuous stable and reliable operation.